Clemson University, MIT and industry join to build battery workforce

October 7, 2025The initiative is aimed at building the workforce in lithium battery manufacturing and recycling, one of the nation’s most critical and fast-growing technology sectors.

The project is funded by the National Science Foundation’s ExLENT program, which supports education and workforce development in emerging technology domains.

Stakeholders in the project include: the principal investigator, Anand Gramopadhye, dean of Clemson’s College of Engineering, Computing and Applied Sciences; Kapil Chalil Madathil, the Wilfred P. Tiencken Endowed Professor of Industrial and Civil Engineering at Clemson University; and Lionel C. Kimerling, Thomas Lord Professor in Materials Science and Engineering at MIT.

Key personnel include: Yet-Ming Chiang, Kyocera Professor of Ceramics, Professor of Materials Science and Engineering at MIT; Beth Unger, a research scientist at MIT; Sajan Saini, education director of the Initiative for Knowledge and Innovation in Manufacturing at MIT; Diana Elrod, director of the Center for Student Research at Texas Woman’s University; and Frank Menchaca, the founder and CEO of Auzolan.

Important collaborators include: the South Carolina technical colleges, South Carolina Manufacturing Extension Partnership, READY SC, professional organizations such as SAE International and NAATBatt International and other industry partners.

The project is the latest example of how Clemson works closely with industry partners, technical colleges, and career and technical education (CTE) programs to develop a strong workforce pipeline. By combining advanced learning technologies with deep industry engagement, the initiative strengthens America’s competitiveness and creates opportunities for students at multiple levels of the education system.

About 20% of the current battery manufacturing workforce exceeds 55 years old, portending a significant worker shortfall within the next decade, researchers found. At the same time, U.S. lithium battery demand is expected to grow six fold by 2030, with more than 120,000 skilled workers needed, researchers found.

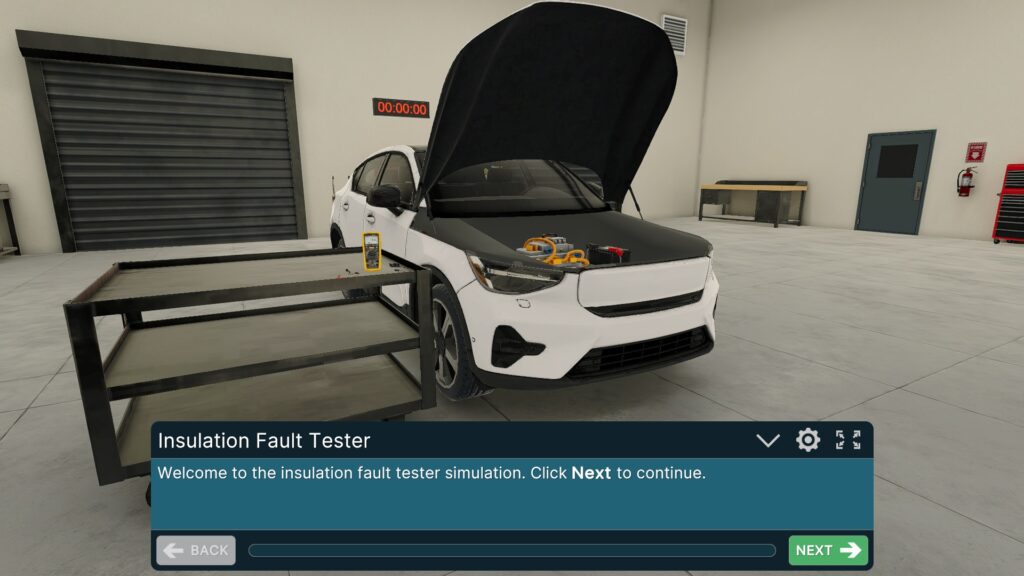

The project team is responding with a strategic workforce development initiative that includes hands-on mentoring, career awareness programs and immersive experiential learning opportunities, including mini video lectures and virtual reality simulations that employ digital twins.

The initiative will be aimed at equipping students with essential skills in production, recycling and innovation.

The project will begin with 240 learners in South Carolina and Michigan, and will be designed to expand nationwide. It will focus on high school students in career and technical programs, students at community and technical colleges and technicians looking to upgrade their skills.

They will learn about areas such as battery safety and recycling and electrode preparation and cell assembly.

Immersive experiences such as industry tours, job shadowing and micro-internships will give them direct exposure to the workplace, while mentoring from professionals will provide critical guidance on career paths.

Students will be able to earn stackable badges tied to course and module completion. With input from SAE International and NAATBatt International, the team will establish a battery manufacturing and recycling certification for technicians.

Researchers will study how well the educational materials work and keep improving the program to match the fast-changing battery industry.

Here is what key partners had to say:

“This project expands the nation’s capacity for battery manufacturing and recycling by strengthening the workforce pipeline. Through collaboration and innovation, we are creating new pathways for students and technicians to enter a technology sector that is key to U.S. competitiveness.”

Angie Leidinger, senior vice president of external affairs and senior advisor to the Board of Trustees at Clemson University

“Our team is developing innovative learning tools, including virtual reality and digital simulations, that connect directly to battery manufacturing and recycling. These methods give students engaging ways to gain the technical skills industry requires.”

Kapil Chalil Madathil, the Wilfred P. Tiencken Endowed Professor of Industrial and Civil Engineering

“Dr. Sajan Saini and our MIT team value this opportunity with Clemson and this team to continue our long-standing partnership for the creation and dissemination of cutting-edge manufacturing content through innovative learning modalities.”

Lionel C. Kimerling, Thomas Lord Professor in Materials Science and Engineering at MIT

“This initiative connects education and industry in ways that directly benefit the energy storage sector in a variety of applications, such as transportation, defense and grid. By aligning training with real workforce needs, the project supports innovation, recycling and the availability of skilled workers in our energy storage industries.”

Frank Menchaca, the founder and CEO of Auzolan, Battery Traceability Lead, LiBridge

“This project reflects the power of collaboration between research universities, technical colleges, and industry. Together, we are fueling South Carolina’s economic growth and strengthening its workforce by creating new training pathways that equip our citizens with the skills to succeed in battery manufacturing and recycling.”

Tim Hardee, president of the South Carolina Technical College System

SOCIAL LINKS

Categories

- Accounting

- Advice

- Architecture

- Banking and Finance

- Business Services

- Commercial Real Estate

- Construction

- Conversations

- Economic Development

- Education

- Employment

- Energy

- Engineering

- Entertainment

- Entrepreneurship

- Environmental

- Festivals & Special Events

- Financial Advisors

- Food

- Government

- Headlines

- Health & Wellness

- Health Care Providers

- Hi-Tech/ Information Tech

- Hospitality

- Insurance

- Law

- Life

- Manufacturing

- Marketing and Communications

- Military

- Non Profit

- Op-Ed

- Philanthropy

- Podcast

- Public Safety

- Residential Real Estate

- Restaurant

- Retail

- Sports

- Technology

- The Arts

- Transportation

SOCIAL LINKS

Categories

- Accounting

- Advice

- Architecture

- Banking and Finance

- Business Services

- Commercial Real Estate

- Construction

- Conversations

- Economic Development

- Education

- Employment

- Energy

- Engineering

- Entertainment

- Entrepreneurship

- Environmental

- Festivals & Special Events

- Financial Advisors

- Food

- Government

- Headlines

- Health & Wellness

- Health Care Providers

- Hi-Tech/ Information Tech

- Hospitality

- Insurance

- Law

- Life

- Manufacturing

- Marketing and Communications

- Military

- Non Profit

- Op-Ed

- Philanthropy

- Podcast

- Public Safety

- Residential Real Estate

- Restaurant

- Retail

- Sports

- Technology

- The Arts

- Transportation

Follow us

Categories

- Advice

- Agriculture

- Chamber

- Echoes & Insights

- Economic Development

- Education

- Employment

- Entertainment

- Environmental

- Festivals & Special Events

- Government

- Health & Wellness

- Health Care Providers

- Hospitality

- Laurens County Sports

- Law

- Local Industry

- Manufacturing

- Marketing and Communications

- Music

- Non Profit

- Public Safety

- Social Scene

- The Arts

- Veterans

Categories

- Accounting

- Advice

- Agriculture

- Architecture

- Banking and Finance

- Business Services

- Chamber

- Churches

- Commercial Real Estate

- Construction

- Conversations

- Economic Development

- Education

- Employment

- Energy

- Entertainment

- Entrepreneurship

- Environmental

- Festivals & Special Events

- Financial Advisors

- Government

- Headlines

- Health & Wellness

- Health Care Providers

- Hi-Tech/ Information Tech

- Home Remodel/ Maintenance

- Hospitality

- Hotels

- Insurance

- Law

- Life

- Local Industry

- Manufacturing

- Marketing and Communications

- Military

- Music

- Non Profit

- Op-Ed

- Philanthropy

- Podcast

- Politics

- Public Safety

- Residential Real Estate

- Restaurant

- Retail

- Social Scene

- Sports

- Telecommunications

- The Arts

- Transportation

- Utilities

Categories

- Advice

- Agriculture

- Chamber

- Echoes & Insights

- Economic Development

- Education

- Employment

- Entertainment

- Environmental

- Festivals & Special Events

- Government

- Health & Wellness

- Health Care Providers

- Hospitality

- Laurens County Sports

- Law

- Local Industry

- Manufacturing

- Marketing and Communications

- Music

- Non Profit

- Public Safety

- Social Scene

- The Arts

- Veterans